Lockout Tagout Training for Authorized Employees

Don’t count on luck, count on the lock. Protect yourself and your team from unintentional exposure to all types of hidden energy with this lockout/tagout (LOTO) course that describes hazardous energy types and energy control procedures, including preparation, shutdown, isolation, lockout, stored energy check, verification, and release of lockout. Additional LOTO course topics include lockout hardware and administration of an Energy Control Program (ECP).

This course is intended for the LOTO “authorized employees” who typically perform lockout/tagout procedures. Please see our Lockout/Tagout for Affected Employees course for those who are not authorized to initiate the lockdown/tagout procedure.

Request a demoCourse Details

Learning Objectives

By the end of this course, you will be able to:

- Define lockout/tagout

- Identify sources of hazardous energy and describe how hazardous energy is isolated

- Differentiate between an “authorized employee” and an “affected employee”

- List the six steps of an effective hazardous energy control program

- Describe the training requirements for lockout/tagout

- Describe the procedure for restarting equipment that had been locked out and tagged out

Specs

| Course Level | Intermediate |

| Languages | English, Arabic, Portuguese, Chinese, Dutch, French, German, Italian, Japanese, Korean, Tamil, Polish, Russian, Spanish, Swedish, Thai, Czech |

| Compatibility | Audio, Video |

| Based on: | 29 CFR 1910.147: The Control of Hazardous Energy (Lockout/Tagout) |

Course Applies To

Key Questions

What is lockout/tagout?

Lockout/tagout refers to specific practices and procedures to safeguard all workers from the unexpected startup of machinery and equipment or the release of hazardous energy during service or maintenance activities. Lockout/tagout can be defined as the placement of a lock or tag on an energy isolating device, in accordance with an established procedure, ensuring that the energy isolating device and the equipment being controlled cannot be re- energized until the locking device is removed.

What are primary energy sources to be isolated during lockout/tagout?

Primary energy sources include electricity, hydraulics (fluids), and pneumatics (air or vacuum energy).

What are secondary (or stored) energy sources to be isolated during lockout/tagout?

Secondary energy sources include springs, capacitors, accumulators, counterbalance systems, gravity, and inertia.

What is an authorized person or employee?

An authorized person is the one who performs the lockout. This is someone who is familiar with the equipment in question and capable of locking it out properly.

What is an affected employee?

An “affected employee” is an employee that is affected by the lockout. This commonly includes machine operators who need to know that their machine should not be operating.

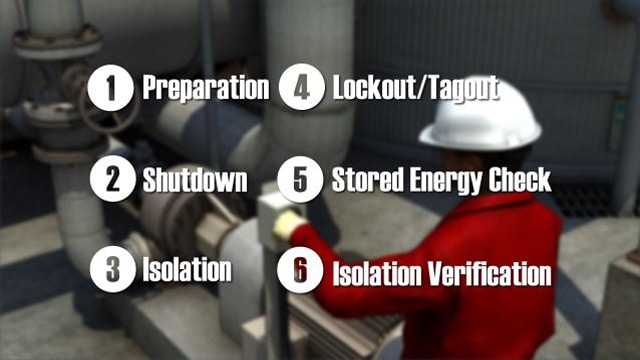

What are six steps to an effective energy control program?

The six steps to an effective energy control program include:

- Preparation

- Shut down

- Isolation

- Lockout/tagout

- Stored energy check

- Isolation verification

What types of hardware are used to lockout machinery?

Locks and hasps are used to lockout machinery for energy control.

Sample Video Transcript

“Hazardous energy can take many forms. Consider the simple task of removing a pump and motor unit from a process. Most people would realize that the electricity to the motor needs to be interrupted and locked out before removal, but there is another source of energy that presents a less obvious hazard, and that some people might not think of. The pump is connected to process piping which probably has pressure within it. Before the pump can be removed, workers must be protected by closing valves or inserting blanks to isolate the pump from upstream or downstream fluid pressure and draining the associated piping.”

Additional Resources

- U.S. Department of Labor’s Occupational Safety & Health Administration (OSHA) – https://www.osha.gov/

- OSHA Control of Hazardous Energy – https://www.osha.gov/control-hazardous-energy

- OSHA Fact Sheet – https://www.osha.gov/sites/default/files/factsheet-lockout-tagout.pdf

- OSHA Typical Minimal Lockout Procedures CFR 1910.147 App A – https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.147AppA

- National Institute for Occupational Safety and Health (NIOSH) – https://www.cdc.gov/niosh/

- NIOSH Publications – https://www.cdc.gov/niosh/docs/2004-101/chklists/r1n44l~1.htm

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.